|

|

Post by brianjenkins on Jun 17, 2015 6:42:19 GMT -5

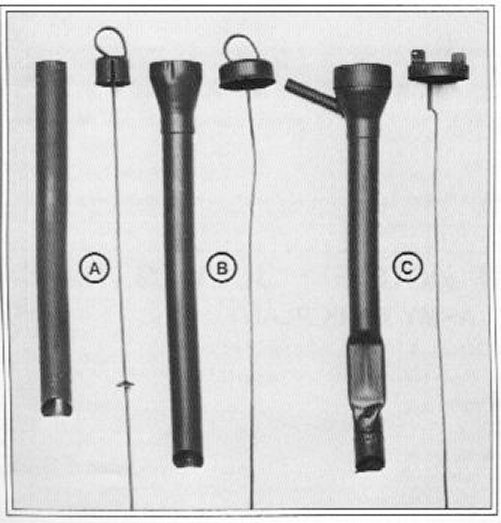

What role does the breather tube play on the oil dipstick tube? I have an early CJ2A that actually has some GPW/Ford components on it. My dipstick tube is the middle one below. I already changed the draw tube and installed a properly fitted PCV valve, but I picked up an Oil Bath air cleaner and noticed it had a nipple on it which would connect to the tube on the right below. Is the vacuum from the air intake needed, or will I get enough vacuum once the PCV valve opens?  |

|

|

|

Post by Scoutpilot on Jun 17, 2015 7:27:31 GMT -5

First. I want to thank Brian for posting the photo and asking the question. This is what I imagined for this site. The answer is that the vacuum pulled through the PCV valve will serve to draw the particulate and volatile gas-laden crankcase air through to the cylinders for combustion. Your system will be mildly more efficient than with (A), but less effective than (C).

All three designs are supposed to accomplish the same purpose. The improvement of (B) over (A) is a greater volume of fresh, albeit dirty, dusty air is allowed to enter the crankcase. (Not to mention, a GI adding oil is less likely to create a mess.) The caps are large and loose-fitting to accommodate the airflow requirement. The improvement offered by (C) over (B) is the airflow now comes from the air filter and is cleaner than with the first two designs. The cap now semi-seals to preclude dust intake. Let's look at the graphic again.

Fresh air is drawn into the Oil Bath Air Cleaner and relieved of the majority of the airborne particulates which are a primary ingredient in the sludge which develops in the crankcase and pan. The cleaner air is drawn into both the carburetor and the dipstick tube by the vacuum created in the cylinders. This vacuum, when properly regulated by means of the PCV valve, draws most of the remaining particulates and now the volatile gases created by heat and the combustion process through the PCV valve and into the cylinders where the concoction is burned and exhausted. It is a constant process while the motor is running. Remember that when you do an oil change, it is a good additional set of steps to clean and refill the Oil Bath Air Cleaner, only to the line, with fresh motor oil. It is also wise to remove and clean the PCV valve at this time.

|

|

|

|

Post by brianjenkins on Jun 17, 2015 23:31:10 GMT -5

Thanks Scout.

There is a baffle on the end of my dipstick to seal against the inside of the filler tube. It's a Ford/GPW dipstick, and apparently they only used these for a few months. It's a JEEP engine, so at some point it was probably a replacement.

How are the tubes attached to the engine? Is it just the top bracket, or are they secured inside the bottom somehow? I'll likely try and change it at some point.

|

|

|

|

Post by Scoutpilot on Jun 18, 2015 3:58:30 GMT -5

The end is tamped into the block for a pressure fit. If yours is too small, you can use a deep well socket to expand it enough for a snug fit. Tamp it in and secure the top with the bracket to help prevent vibration loosening.

|

|

|

|

Post by Ed on Apr 5, 2016 23:52:41 GMT -5

Thanks for all the great info and videos.

I have two willys with the L134 engines. One has a late model pcv valve (rattle type) that is screwed in but the valve cover side is spotless after 2 years like no oil fumes have passed through the valve and into the intake. The other 134 had all the pcv stuff removed and changed over to down draft tube. Doing some research it appears that just because a pcv valve may screw in does not mean it will work as design in this system. Since I need 2 pcv valves I want to make sure I get the correct ones. What I am looking at is expensive plus since I live in Canada I will be paying 25% more in money exchange and whole pile of shipping and boarder fees.

The question is...does the correct pcv have a hole drilled directly through it? Reports have it that venders are selling WO A6895 units and when they arrive they have a hole drill straight through it. On the other hand, ones marked CV476 that look the same have no hole and seal. What is correct?

Thanks

|

|

|

|

Post by Scoutpilot on Apr 6, 2016 3:53:44 GMT -5

Hey Ed. The first question I have is directed at the first motor. What does the oil look like? Any grey foam inside the oil filler tube or on the dipstick? If it is clean, then I can only assume you drive it a lot. It reaches and stays at operating temperature for an extended amount of time. Everything is working as designed. The Draft Tube is all right as long as you do not ford any deep water. The visuals I’ve placed in this thread show the correct design and structure of a spring loaded valve actuated by vacuum. I am unaware of any proper aftermarket valve that has a hole drilled straight through either linearly or otherwise. There is one on the market that cannot be disassembled for cleaning. Why? I don’t know and can’t get an answer. Your best bet is to search for NOS. As an afterthought, is there a conical screen inside the pickup tube in the valve cover? If so, remove it and put it up on the shelf. This design has been known to collect trash and sludge, blocking the pickup tube.

|

|

|

|

Post by k9hdlr on Dec 9, 2016 12:35:33 GMT -5

Just ran in to this thread and realized that my set up does not have a PCV valve that I'm aware of. The tube from the oil filler/dipstick has a hose that runs straight up to the air tube running between the oil bath filter and air horn. Should I purchase a PCV valve and place it in the hose? Second, there is the metal tubing that runs out of the fitting on the valve cover gasket. Is this the second PCV that people have mentioned?

Thanks for the info... btw, my newly restored Carter WO runs beautifully! Thanks so much for the great work restoring it!!!

Andy

|

|

|

|

Post by Scoutpilot on Dec 9, 2016 17:52:13 GMT -5

Thanks for the flowers Andy. Click on this link to learn exactly what you need. Try that again.

|

|

|

|

Post by k9hdlr on Dec 9, 2016 20:09:17 GMT -5

Thanks for the flowers Andy. Click on this link to learn exactly what you need. PCV So I clicked on the link "PCV" and it just opens this same page... am I missing something? lol |

|

|

|

Post by Scoutpilot on Dec 9, 2016 20:20:55 GMT -5

|

|

|

|

Post by btinsc on Oct 26, 2018 17:31:19 GMT -5

Found some great reading here. I enjoy reading how things are suppose to work and am finding answers to a lot of my questions here on this great site.

My new to me ‘52 3A is a little smokey. I will get deeper into it after deer season but for now I pack an external quart or two of oil.

My question pertains to the pcv valve. Due to finding the current valve stopped up with crud I replaced it. I installed the new valve and with the tube to the valve cover not installed I started the engine.The engine started as usual. I then put my finger on the valve inlet and the engine died. Tried it again with the same result. What’s going on here? I was surprised that the engine required that much air thru the pcv valve to operate. Is it the air/ fuel mixture disturbance that is causing the engine to shutdown?

If it makes any difference the engine has a Solex carb on it. I have now have two Carter Wo carbs cores to be rebuilt, anyone know anyone who can build them for me?? Lol

|

|

|

|

Post by Scoutpilot on Oct 26, 2018 18:14:32 GMT -5

No. The air/fuel mixture includes crankcase air/gases/particulates/water vapor. Absolutely necessary.

I might know someone, who knows someone, who knows...

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 26, 2018 21:21:50 GMT -5

Interesting!, I believe A & B in Brian’s photo we’re early production, A, perhaps predating the Jeep. B being an early GPW would most likely had a “Road Draft Tube” on the tapper cover and no PVC settup.

Lee

|

|

|

|

Post by btinsc on Oct 27, 2018 9:40:36 GMT -5

The carbs throttle plate would have been closed at idle. Is that why the engine stopped when I blanked off the flow thru the pcv ? No big deal, I'm just curious.

|

|

|

|

Post by Scoutpilot on Oct 27, 2018 11:11:06 GMT -5

Blocking the air flow caused the mixture to suddenly be fuel rich and air poor.

|

|